Click to enlarge

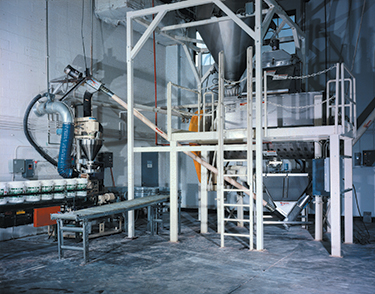

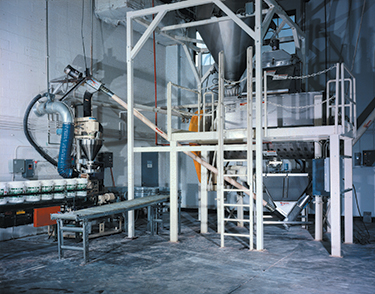

Click to enlargeAfter the product blending, two flexible screw conveyors transport product in opposite directions. The smaller conveyor on the left feeds a small batch packaging line.

Click to enlarge

Click to enlargeThe larger flexible screw conveyor loads product into a 100-cubic-foot surge hopper, freeing the blender's discharge hopper to receive additional product.

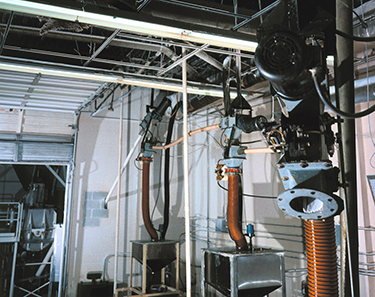

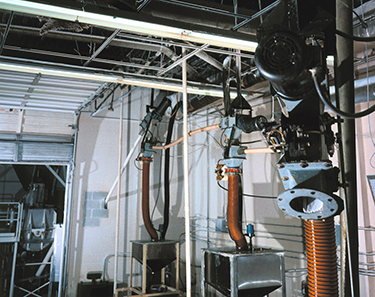

Click to enlarge

Click to enlargeThe inclined conveyor drops product to a packager beneath it or transfers product to horizontal conveyors feeding two other packagers.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge